NEWS

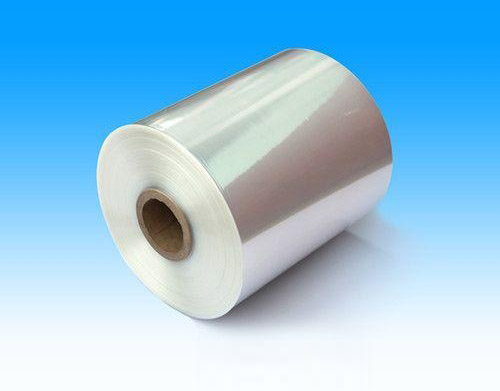

The difference and advantage of POF heat shrinkable film and other shrinkable films

- Clicks:3423

- 2018/4/25 13:04:20

- Industry dynamics

The proportion of POF is 0.92, the thickness is 0.012mm, the actual unit cost is low. The proportion of PE is 0.92, the thickness is thinner than 0.03, the actual unit cost is higher. The proportion of PVC is 1.4, the thickness is 0.02mm, the actual unit cost is higher.

2. physical property

POF thin and toughened, moisture resistant, soft, high tensile strength, high tensile strength, high tear strength, adjustable shrinkage, better rubbing resistance because of the existence of LLDPE, PE thick and toughened, uniform thickness, good moisture resistance and soft texture. The tear strength is lower than POF, but far higher than PVC and poor in shrinkage. The resistance to rubbing is not as thick and brittle as POF. PVC and is not brittle and thick and thin. They all have poor moisture resistance, hard and brittle texture, low strength, low shrinkage and poor rubbing resistance.

3. cold resistance and other physical properties

POF cold resistance is very good, -50 C is not hard and brittle, not easy to break, can be used in frozen food packaging. After contraction packaging, -50 C --95 C is stored for a long time, stable and stable. Static and anti fogging treatment, not easy to pollute the dust, can keep the product clean and bright.PE cold resistance, in winter or after freezing, not hard, not brittle, so transportation is not easy to break Crack. It has electrostatic elimination treatment, not easy to dye dust, can keep the product clean. PVC cold resistance is very bad, in winter or after freezing, it will be brittle, so the transportation is easy to break. The longer the contract packaging, the tighter the contraction will be, the packaging is deformed. It is easy to stain the dust and make the product pollution blur.

4. processing performance

POF process does not produce water and will not stick to the seal. Maintenance and operation are easy. High toughness, smoothness and rubbing resistance make it suitable for automatic packaging of high speed production line. PE processing does not produce water, does not stick to sealing rod, easy maintenance and operation. High Toughening, low kneading, can be used for automatic packaging of high speed production line. PVC plus The process will produce volatile, easy to cause mechanical damage, and easy to stick on the sealing rod, the operation is inconvenient, maintenance is difficult.

5. security

After the POF contraction package, the four corners of the seal are soft and can not cut the hands and rub. After the contraction of PE, the seal is soft and can not cut the hands. After PVC contraction packaging, the four corners of the seal are hard and sharp, and it is easy to cut and bleed.

6. Environmental Hygiene

POF is non-toxic and does not produce toxic odor when processed. It is in line with the FDA and USDA standards of the United States. PE is non-toxic. It does not produce toxic gas when it is processed. It is in line with the FDA and USDA standards of the United States. PVC is toxic. Processing produces odors and toxic gases are gradually prohibited.

- Previous

- none